Designing Interactive Materials

Designing interactive materials bridges material science and interaction design approaches to creating tangible, shape-changing, and material-driven interfaces. This competency encompasses understanding material characteristics (TR, MDC), digital and traditional fabrication techniques (TR, CA), and sensory engagement (US, CA). Simultaneously, integrating this material-driven approach with shape-changing and multisensory interface design lets people connect to technology through meaningful experiences.

Reflecting on Project 2, developing haptic navigation wearables for the Veluwe National Park served as a trigger to realise how materiality can blend the line between computers and objects (TR). This project took my baseline understanding of user interfaces being screens and demonstrated how tangible interaction can provide more enriching experiences.

My engagement with the Aesthetics of Interaction course highlighted the importance of experience prototyping for designing tangible interaction; physical prototypes provoke iterative reflection (CA, TR). In Design and Sensorial Form, I expanded my understanding of multisensory interactions by methodically selecting materials and integrating sound to enhance experiences (US, CA). Digital Craftsmanship deepened my skills in digital fabrication, teaching me to use data in new forms and use materials as expressive mediums (TR, CA, MDC). These experiences made me understand materiality beyond functional goals.

In ChaffCo (Project 3), I worked only with one material to explore the extremes of my interest. This project allowed me to develop an understanding of materials’ experiential properties (CA) while learning and developing new fabrication methods (TR). My honours project further developed my material characterisation knowledge and experimental skills (MDC, TR) as I worked on creating 3D printable wood for construction.

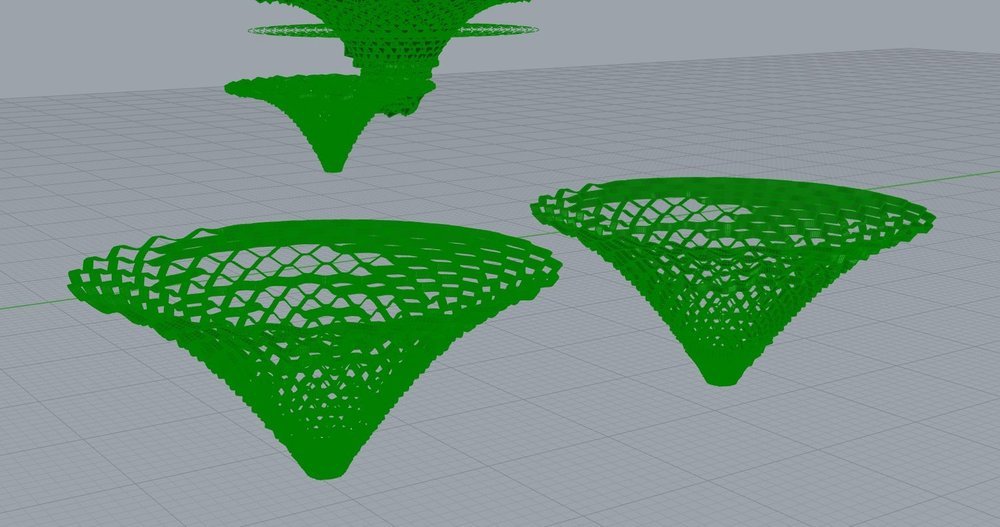

I developed this competency best through my Final Bachelor Project (FBP) in magnetic soft robotics, creating shape-changing forms for designers and reflecting on samples' behaviour from an experientially focused lens using the ‘Material-Driven-Design’ process (CA). Conducting a literature review allowed me to understand the cutting edge in soft robotics and shape-changing interfaces (click to see report). In fabricating magnetic silicone structures, I augmented my digital fabrication skills by creating complex 3D printed and laser-cut moulds (TR). Programming the structures necessitated learning how magnetic domain arrangement and magnetic torque could be leveraged to predict deformation (MDC). This informed the folding techniques and fixtures created to program the forms (TR). Simultaneously, creating the experimental ‘table’ and ‘sticks’ showed me affordances in practice, applying theories outside course contexts. This experience taught me the importance of critical evaluation when working alone, and the challenges of taking advanced materials out of lab contexts, highlighting a need for close interdisciplinary collaboration.